limits of hardness test to find material properties|hardness and strength of materials : manufacturer Properties include elastic modulus, ductility, hardness, and various measures of strength. Mechanical properties desirable to the designer, such as high strength, usually make .

webO PEITO MAIS GOSTOSO DO XVIDEOS. 22 sec Orgasmilk - 9.4M Views -. Show more related videos. 9. XVIDEOS Xehli g rabuda rebolando free.

{plog:ftitle_list}

Reload page. 1,909 Followers, 1,552 Following, 18 Posts - See Instagram photos and videos from Site Eu Confesso (@siteeuconfesso)

On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion resistance).The principle of electronically controlled and permanently monitored load application .

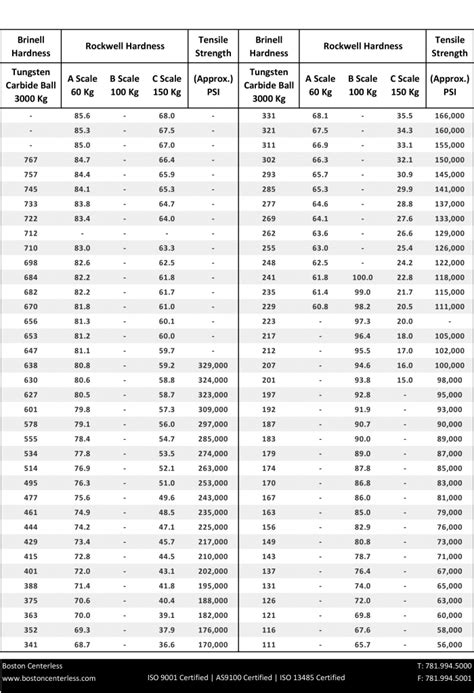

Hardness and Strength • Studies have shown that (in the same units) the hardness of a cold-worked metal is about three times its yield stress (YS), for annealed metals, it is about five .Brinell Hardness Test In this test, a relatively large steel ball, specifically 10 mm in diameter is used with a relatively large force. The force is usually obtained with either 3000 kg for relatively .There are several frequently used methods to measure the hardness of metals, including: 1 Rockwell Hardness. The Rockwell hardness test measures the depth of penetra-tion of an .Properties include elastic modulus, ductility, hardness, and various measures of strength. Mechanical properties desirable to the designer, such as high strength, usually make .

standards for hardness testing

Hardness, a key property of materials, can be categorized into various types, each assessing different aspects of a material’s resistance to deformation. The three primary types are scratch, indentation, and rebound .

Tensile Strength Tester traders

Introduction. Hardness is the resistance of the material to plastic deformation induced by indentation. Hardness test is considered the most rapid test and the most popular . Measuring the hardness of materials is a fundamental aspect of material science and engineering, involving various test methods each suited to specific types of materials and applications. These methods not only help in .

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can . Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work.

Brinell hardness of tin bronze – UNS C90500 – gun metal is approximately 75 BHN. Rockwell hardness of copper beryllium – UNS C17200 is approximately 82 HRB. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work.The yield point is the point on a stress-strain curve that indicates the limit of elastic behavior and the beginning plastic behavior. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration .engineer or as a check on the standard of raw materials [1]. Mechanical properties may be changed by heat treatment process and the working temperature. Mostly, the strength, toughness and hardness of materials are to be measured after the metal forming process [2]. The main objective of the paper is to

Explore material properties in mechanical engineering with this comprehensive guide. Dive into hardness, stiffness, strength, toughness, fracture toughness, and impact strength. Understand definitions, measurements, and more.The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .Note in Figure 2 that the stress needed to increase the strain beyond the proportional limit in a ductile material continues to rise beyond the proportional limit; the material requires an ever-increasing stress to continue straining, a mechanism termed strain hardening.

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work.limits are shown in Table 1. . Hardness Rc 36-or equivalent Stress Rupture Stress, ksi - 72.5 Life, hr - 23 Elongation, % - 5 aUp to 0.025-in. thickness, inclusive. bOver 0.025-in. thickness. cLongitudinal. . Table 6 - Mechanical Properties Aged Material for Oil Tool Applications The hardness test according to Brinell (for wood and wood-based materials according to EN 1534) is the most commonly used static test method. A polished steel ball (diameter 2.5, 5, or 10 mm) is pressed into the sample within a certain time with a defined force F (100–1000 N) and the diameter of the indented spherical cap is measured (Fig. 9 .3. Mechanical Properties of Materials 3.1 Stress-Strain Relationships 3.2 Hardness 3.3 Effect of Temperature on Properties 3.4 Fluid Properties 3.5 Viscoelastic Properties 2 Mechanical Properties • A material’s behavior when subjected to mechanical stresses (load) – Properties include elastic modulus, ductility,

It is evident in Fig. 3.1 that the mechanical properties/behaviors of metals can be divided into four groups: (a) elastic properties, (b) plastic properties, (c) fatigue behavior, and (d) creep behavior. Elasticity refers to the ability of a material to be deformed under load and then return to its original shape and dimensions when the load is removed.graphite material properties and explain their testing methods. These properties also highlight why our materials are industry leading. The purpose of this document is to introduce the reader to graphite properties and to describe testing techniques that enable true comparisons between a come in many grades, each designed for a specific

ASTM A36 Steel. ASTM A36 steel is one of the most widely used carbon structural steels, although the carbon content of A36 material is maximum 0.29%, it is considered to be the mild steel (content of carbon ≤ 0.25%).. A36 mild steel is often compared to AISI 1018, A36 carbon steel is commonly hot rolled, while 1018 steel is commonly cold rolled.. Notes: There are two . #6 Hardness. The resistance of a material to force penetration or bending is hardness. Hardness is the ability of a material to resist scratching, abrasion, cutting, or penetration. Hardness indicates the degree of hardness of a material that can be imparted particularly steel by the process of hardening. This study presents a new methodology for predicting the ballistic performance of armor steels based on their mechanical properties. Plates were developed as candidate armor steels, and the mechanical properties (hardness, strength, impact toughness, and total elongation) were determined for each. A pass/fail criterion was established, and the values of .The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten .

The application of hardness testing enables you to evaluate a material’s properties, such as strength, ductility and wear resistance, and so helps you determine whether a material or material treatment is suitable for the purpose you require. . Vickers is a hardness test for all solid materials, including metallic materials. The Vickers . fatigue limit; elongation (relative) at break; hardness. The mechanical properties of materials, including aluminium and its alloys, that are obtained by tensile testing of the material, such as tensile modulus, tensile strength, tensile yield strength and elongation, are called tensile mechanical properties. . relative to the original length .

Type 303 Stainless Steel Properties. The following datasheet give 303 stainless steel properties including chemical composition, physical and mechanical properties, heat treatment, welding, etc. Chemical Composition. SS 303 material chemical composition is listed in the following table based on cast analysis.SAE AISI 4140 Alloy Steel. SAE 4140 (AISI 4140 steel) is a Cr-Mo series (Chrome molybdenum series) low alloy steel, the material has high strength and hardenability, good toughness, small deformation during quenching, high creep strength and long-lasting strength at high temperature. 4140 Steel Uses. AISI SAE 4140 alloy steel can be made into round steel bar, flat & square .

Login to your account. Remember Me Register a new account Lost your password?. Canais

limits of hardness test to find material properties|hardness and strength of materials